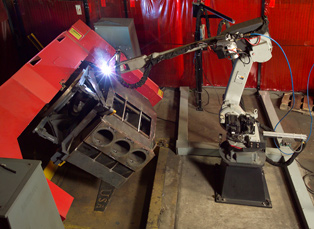

Robotic Welding

As a progressive company, at Signal Metal Industries, Inc. we leverage state-of-the-art robotic welding technologies to provide quality, high productivity, and cost-efficient welding services. Specializing in larger than standard robotic welding of intricate weldments, we have the advanced technical skill required to perform the complex programming setups associated with multi-stage welding. Our high-tech CAD/CAM capabilities allow us to produce extremely accurate and repeatable high quality welds.

Our equipment assets include a six-axis floor mounted robotic welding system with dual, 5,000 lb. capacity center drop positioners. Capable of both gas metal arc and flux core welding, this system features a control system capable of high-performance path accuracy over a full 360° range of circumferential motion and a 122" reach. Its seam tracking sensing technology allows us to track joints at high speed in real-time to ensure consistent performance with no deviation. This work cell also incorporates a 10-ton overhead crane axis as well as an upper level observation deck that affords us full visibility into welding operations from a safe vantage point.

Our turnkey welding services include in-house fixture design. We are extremely proficient at building fixtures that align and hold large, challenging parts at complex angular orientations to achieve maximum weld quality and accelerated throughput. Our facility also offers NDT and inspection equipment for certifying weld quality.

By combining our expert knowledge of welding processes and robotic movement, we achieve a high level of accuracy at fast cycle times. Robotic welding allows us to keep labor costs low and offer very attractive pricing. To learn more about our robotic welding capabilities, contact us today.

Robotic Welding Capabilities

- General Capabilities

-

- Build to Print

Turn Key - Specialized In-large Weldments

Complex Weldment Programming

- Build to Print

- Types

- 6- Axis Floor Mounted with Center Drop Duel Positioners

- Features

-

- 6-Axis Robot and NX 100 Controller

Full Automated Safety Light Curtain System

Seam Tracking - ComArc Sensing Technology

Overhead Observation Deck

10 Ton Overhead Crane Axis

- 6-Axis Robot and NX 100 Controller

- Robotic Equipment

- Moto Man Duel Cell Duel Drop Center Positioner with an access 450 Miller Welder

- (2) 5,000 lbs. Capacity Duel Positioners

- 360° capabilities with an overall reach of 122"

- Fixtures

- In-house Fixture Design

Dual Positioner

- Robotic Welding Capabilities

- Gas Metal Arc Welding

Flux Core Arc Welding

- Materials

-

- Carbon Steel

Stainless Steel - High Strength Low Alloy

Alloy Steel

- Carbon Steel

- Software Used

- 2D AutoCAD LT

3D SolidWorks

Additional Information

- Industry Focus

-

- Aerospace

Agricultural

Architectural

Auto/Truck/Transportation

Chemical

Construction

Food

Heavy Industry - Machine Tool

Marine

Military

Mining

Oil Field

Steel Mill

Packaging/Converting

Power Generation

- Aerospace

- Industry Standards

-

- ISO Compliant

AWS

ASME - AIST

ANSI

CSA

- ISO Compliant

- File Formats

-

- AutoCAD (DWG,DWZ)

SolidWorks (SLDPRT,SLDDRW,SLDDRT)

BMP

DXF

GIF

IGES

Inventor (IDW, IPT)

JPG or JEPG - MasterCam (MDX, MC8, MC9, SET)

PDES

PDF

STEP(DSN)

GIBBS Cam

TIFF

- AutoCAD (DWG,DWZ)

Print This Page

Print This Page